MOVE ARROWS BELOW

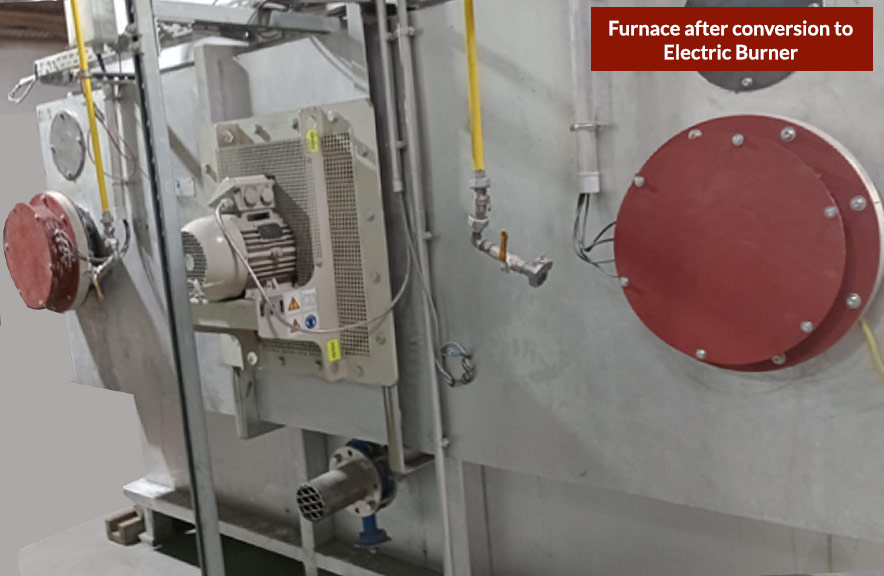

With rising energy costs, eliminate fossil fuels from your heat treatment processes and learn about the cutting-edge, competitive, sustainable, and CO2-free production method with enormous energy-saving potential!

Next Steps

Personal consultation: Schedule a meeting with one of our professionals, and they will demonstrate the unique benefits of the electric burner for the different thermal processes in your business.